Rivets

Rivets

Rivets originated in the Bronze age swords or daggers have been found with rivets as the fastening method. Amazing to think that good ideas/technology can last multiple millennia.

Types

Buck and Blind rivets are the primary rivet types used on the airstream

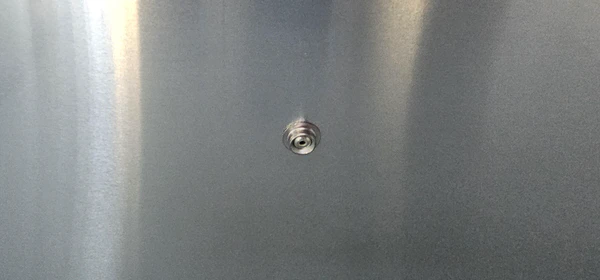

Buck rivets (Solid Rivets)

Buck rivets are usually on the outside of the airstream, they are use to hold the structure together. These rivets are strong, vibration resistant, and require access to both sides of the material in order to be joined. If you are replacing a Buck rivet, you are compressing the shaft of the rivet from both sides.

Blind rivets (Pop Rivets)

Blind rivets are usually installed inside the airstream, holding the internal skin to structure. It’s common for blind rivets to fail under a variety of conditions. Blind rivets are robust. It is important that when blind rivets fail, they get replaced. Multiple failed connection points supplied by blind rivets is likely to cause a cascading failure of other rivets providing mechanical fastening.

Replacing Blind rivets

I keep on hand 10-30 1/8x3/8 Aluminum rivets in the airstream, in case they are needed when we travel. I however don’t replace rivets when we are on the road unless absolutely needed. I prefer to replace them when we retrun home. Almost always a drill, masking tape, and a vacumn are needed. Additionally I like the time savings and stress free environment of fixing things when we are at home.

When I replace rivets I will always use masking tape to provide protection to the skin/clearcoat around the affected area. The masking tape prevents scratches from various implements during the replacement process.

I scratched the inside of Olive with my rivet gun head on the first rivet replacement. Now I try my best to prevent scratches.